Professional Product Testing

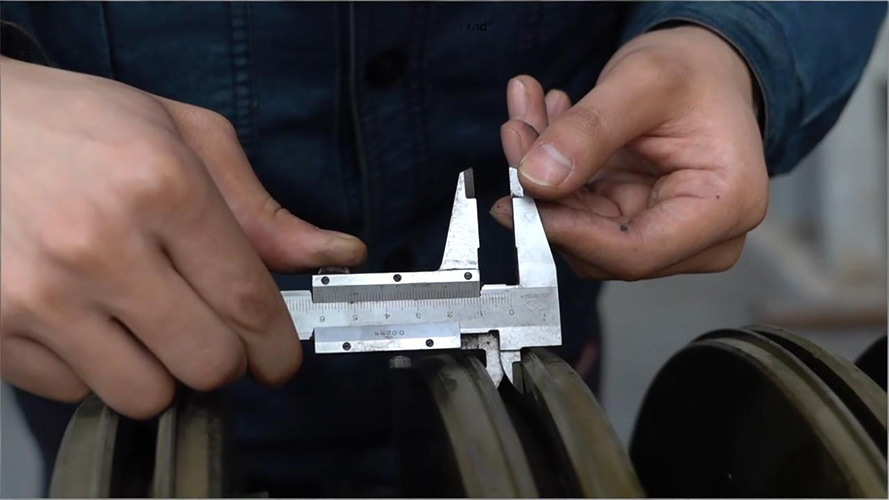

Our company has established a comprehensive professional product inspection system that covers the entire testing process for steam turbines and cement kiln supporting equipment. This includes high-precision performance testing, sealing tests, dynamic balancing testing for rotating components, and more, with each core indicator—such as product precision, operational stability, and safety performance—rigorously verified item by item. For instance, dynamic balancing testing precisely eliminates potential vibration hazards during equipment operation; mechanical inspection and measurement strictly control component dimensions and assembly fit accuracy; and dye penetrant testing efficiently identifies concealed defects such as fine surface cracks on workpieces. The entire process strictly adheres to industrial testing standards, ensuring that all product performance metrics meet specifications and providing solid assurance for the long-term stable, safe, and reliable operation of the equipment.